Chapter 6 "Selection of Idea (2)"

- GroundnutSheller Team

- Apr 14, 2020

- 1 min read

Updated: Apr 16, 2020

As we approached the end of phase 2, we realized that the conclusion we had come up with had been premature, because we had done our analysis comparing the different features of the groundnut sheller, rather than the different ideas in each subsystem. Thus, we revisited our three subsystems which are power, shelling and separation.

The power subsystem

Our sheller could be hand driven, pedal driven or motor driven. To evaluate this criteria, we used a Pugh chart.

From this analysis, we concluded that the existing pedal driven design was better than either the hand-driven one or the motor driven one.

Shelling Subsystem

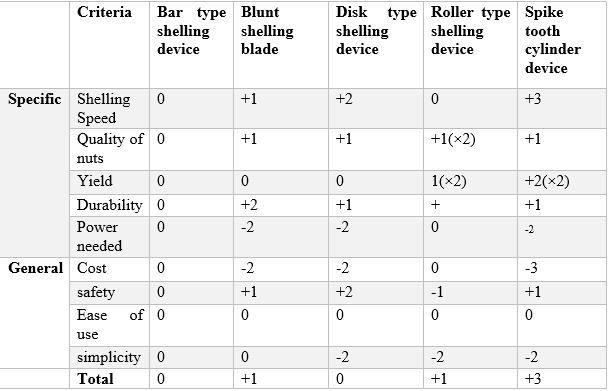

The existing shelling system was a bar-type shelling device. Thus, we also considered if the blunt shelling blade, the disk type shelling device, the roller type shelling device or the spike tooth cylinder device would better meet the needs of the user.

Likewise, we used a Pugh chart for this analysis.

We cam to the conclusion that the spike tooth cylinder device would work best in the shelling process.

Separation Subsystem

The current system has no device to allow for separation of the nuts from the shells after the shelling process. And the farmer had to do manual separation. Thus, we also considered the viability of using a motor-powered sieving bed, a pedal driven blower

or a semi-circular mesh for the separation.

From this, we concluded that a motor-powered sieving bed was the best approach for the separation subsystem.

UNTIL NEXT CHAPTER IT IS A BUH BYE!

Comments